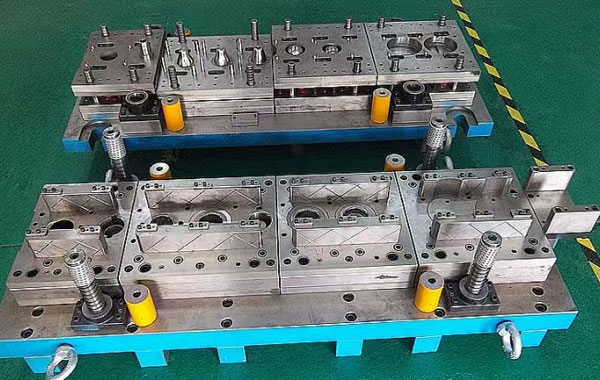

Stamping dies are critical tools in the stamping process, and their precision and condition directly impact product quality, production efficiency, and die lifespan. To ensure long-term stable operation, reduce failure rates, and extend service life, proper daily maintenance of stamping dies is essential. The following are the key aspects of daily maintenance:

1. Cleaning and Care

After each use, the die should be thoroughly cleaned. Remove residual materials, metal shavings, lubricant, and oxides from cavities, guide posts, guide bushings, and other areas. Specialized cleaning agents and brushes should be used when necessary to avoid damaging precision surfaces.

2. Lubrication and Rust Prevention

Guide components (e.g., guide posts and bushings) and moving parts should be regularly lubricated to ensure smooth operation and reduce wear. To prevent rusting—especially during downtime or storage—anti-rust oil should be applied to working surfaces and mating parts.

3. Inspection and Repair

Before each shift, inspect key die components such as punches, die inserts, and stripper plates for cracks, chipping, wear, or looseness. If abnormalities are found, stop the machine immediately for maintenance. Minor wear should be promptly repaired (e.g., grinding or polishing), while damaged parts should be replaced to maintain the overall die performance.

4. Fastener Management

Due to operational vibration, fasteners such as screws and pins may loosen over time. Regularly check the tightness of all fasteners, and apply anti-loosening measures (e.g., thread-locking adhesives or spring washers) where needed to prevent misalignment or damage.

5. Clearance Control

Prolonged use can alter die clearances due to wear, affecting product accuracy and stamping stability. Regularly inspect and adjust die clearance as necessary. Refit punches and dies when needed to maintain optimal assembly precision and uniform clearance.

6. Operation Records and Maintenance Logs

Maintain comprehensive records of die use and maintenance, including cleaning, repairs, failures, and component replacements. This helps track performance trends, anticipate potential failures, and implement targeted maintenance strategies.

By implementing systematic and well-planned daily maintenance, die life can be significantly extended, and production consistency improved. Establishing standardized maintenance procedures and training operators accordingly is essential for integrating die care into routine production management.