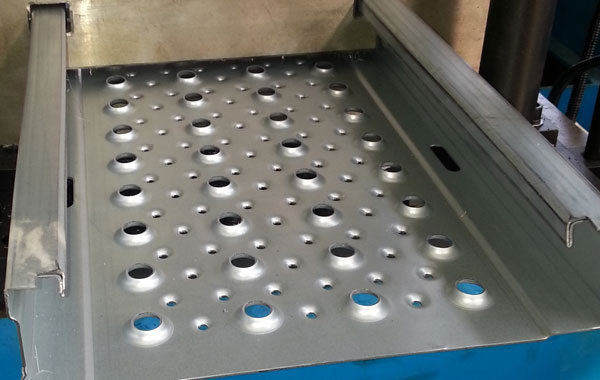

It is great significance about the selection of materials to ensure the smooth progress of the stamping process and meet the quality requirements of the stamped parts. Improper material selection often leads to issues such as cracking, wrinkling, and dimensional instability. Therefore, in stamping production, choosing appropriate materials based on the product’s characteristics and process requirements is a critical task that can’t be overlooked.

1. Satisfy Basic Mechanical Property Requirements.

The material must possess sufficient strength and rigidity to ensure that the part does not deform or fail during service. For parts requiring deep drawing or complex forming, good plasticity and high elongation are also essential to prevent cracking.

2. Exhibit Good Formability. Ideal stamping materials should meet the following criteria:

A. Uniform thickness and dense internal structure, which facilitate dimensional control during forming;

B. Low yield-to-tensile strength ratio, which enhances deep-drawing performance;

C. Smooth and defe0ct-free surface, which contributes to prolonged tool life and improved surface finish of the final product.

3. Ensure Stable Performance and Batch Consistency.

Even if materials meet the required specifications, significant variations between batches can lead to unstable stamping performance. Therefore, it is advisable to source materials from reputable suppliers with proven quality consistency to minimize fluctuations in production.

Material selection may seem straightforward, but in reality, it is a complex engineering decision involving product performance, formability, and cost control. Only by thoroughly understanding the material properties and forming requirements can one make sound and rational choices, thereby ensuring both the quality and efficiency of stamping production.